- Home

- Foundry Solutions

- Design Service

- Investor Relations

- Press Center

- Career

- Corporate Social Responsibility

- About SMIC

Mask Operation

Mask Operation

SMIC's mask operation provides mask manufacturing services for SMIC's foundry customers and other FABs and institutions. Equipped with state-of-the-art tools, the facility offers binary masks and phase shift masks complete with optical proximity correction. Both 5"×5" and 6"×6" reticles are available for G-line, I-line, DUV and ArF steppers and scanners.

In-House Service Benefits

Customers utilizing SMIC mask services as part of a turnkey solution can enjoy benefits such as a shorter cycle time from tape-out to wafer start, reduced risk of reticle damage during transportation, increased flexibility of services and cost savings. In addition, they can benefit from the convenience of online mask data review and job deck view services.

Mask Operation Quality

Stringent quality control at our mask operation, coupled with our strong technology development team, enables us to produce masks under tight critical dimensions with low defect rates. Each mask set is recorded in our mask status tracking system and vigilantly monitored to ensure delivery of quality reticles. Regular checks help to detect and prevent ESD damage, scratches, particles, pellicle frames and aging.

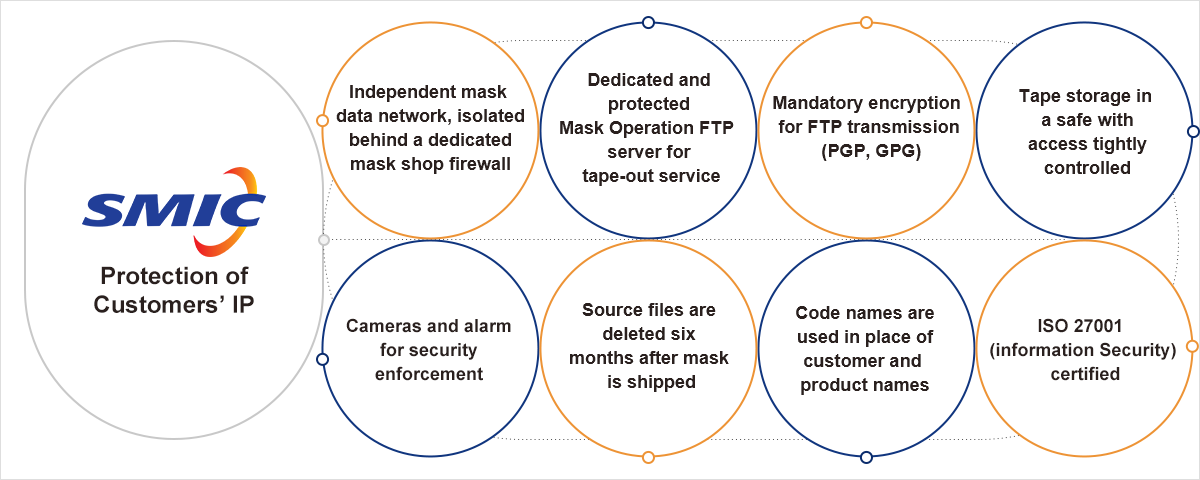

Mask Operation Security

SMIC's mask operation exercises tight security control to ensure protection of our customers' intellectual property (IP). A secure and access-controlled mask operation production environment is backed by tight mask operation network and protected behind an isolated and dedicated mask operation firewall. Data and network security measures include the following:

Other Pages Of Services