- Home

- Foundry Solutions

- Design Service

- Investor Relations

- Press Center

- Career

- Corporate Social Responsibility

- About SMIC

Quality & Reliability

Quality & Reliability

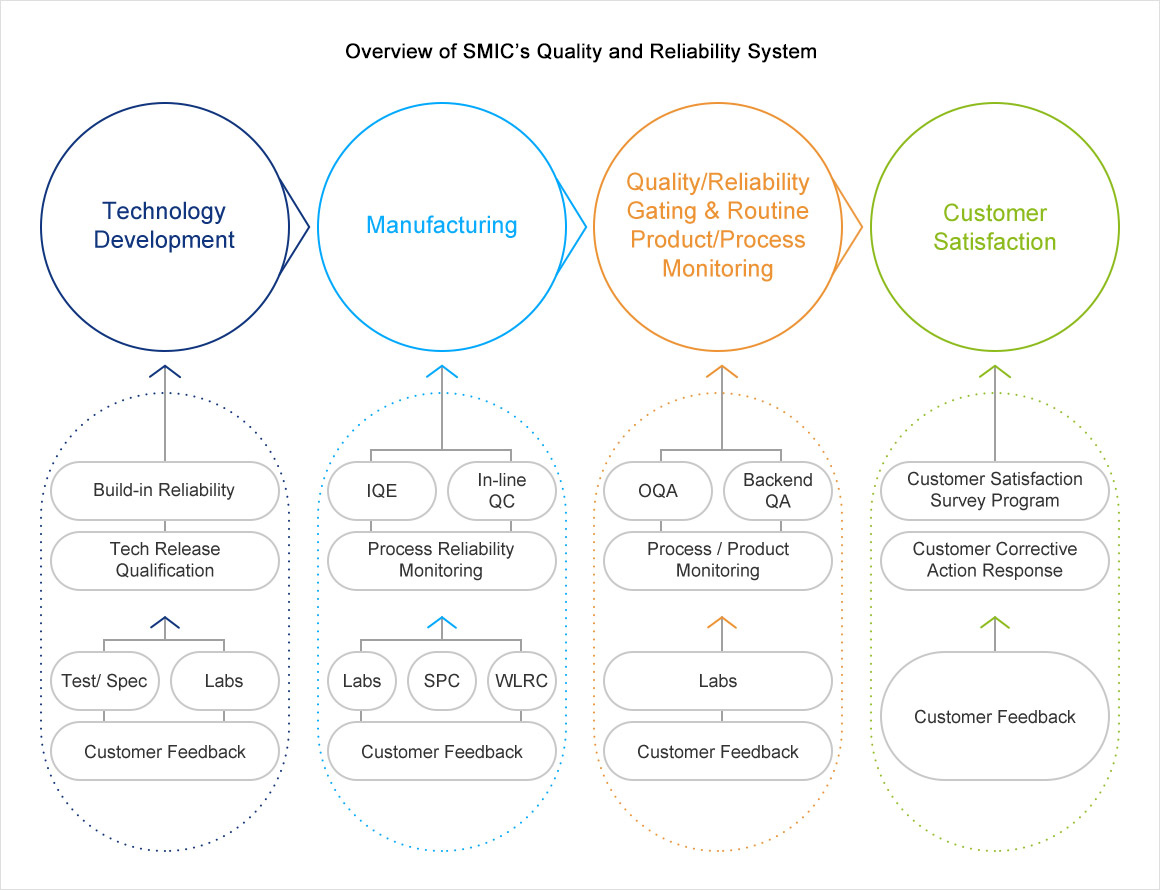

SMIC has built comprehensive quality and reliability assurance and control systems into our processes and services from technology development to production. In addition, we have various labs and analytical tools to perform chemical and material analysis, product failure analysis and yield enhancement, reliability qualification and monitoring, as well as tool calibration.

To ensure a consistent level of quality and flexibility for our customers, SMIC uses a "One Mega Fab" concept whereby all equipment and process recipes are tuned to achieve the same wafer acceptance test (WAT) and yield results at any of our fabs.

-

Quality & Reliability System

To achieve high-quality delivery of our services, SMIC integrates quality standards and procedures through our entire operations chain. These include:

01Built-in reliability in our technology development and production processes

02Process reliability monitoring during manufacturing

03Strict quality control of incoming raw materials and outgoing wafers

04Stringent monitoring of in-line processes

05A built-in reliability database that tracks wafer, package and product level reliability through the development, qualification and production stages

06Implementing statistical process control (SPC) and wafer-level reliability control in mass production for fast feedback and continuous improvement.

07Product quality monitoring

Legend:

IQE: Incoming Quality Engineering (Including Incoming Quality Control and Supplier Quality Assurance)

WLRC: Wafer Level Reliability Control

OQA: Outgoing Quality Assurance

SPC: Statistical Process Control

-

Quality Management System

The pursuit of quality is a continuous effort at SMIC. To maintain a high level of quality in our work and processes, SMIC emphasizes clear and concise process definitions, standardized procedures, well-defined responsibilities, detailed documentation of customer requirements, wafer performance and production analysis, and a high level of customer transparency.

As part of our quality management system, SMIC continuously works to ensure:

01Customer requirements and internal quality standards are fully communicated, understood and adhered to;

02On-time delivery of high-quality services; and

03Continuous improvement in service and product quality and reliability through the implementation of our PDCA (plan, do, check, act) steps, together with internal and external customer feedback.

Download Certificate:ISO9001 Quality System Certificate

IATF16949 Quality System Certificate for Automotive Production and Relevant Service Parts Organizations

TL9000 Quality System Certificate for Information and Communications Technologies Industry

-

Information Security Management System

To protect our organization’s core business and improve competitiveness, SMIC maintains a comprehensive information security management system, including four basic components: employee management, information technology application, rules and policies establishment, and audit implementation.

As part of our Information Security Management System, SMIC continuously works to ensure:

01Always prioritize the security of customer information

02Properly protect all information assets

03Conduct risk management to ensure business continuity and minimize losses if the information system is affected

As a reflection of our dedication to information security management, we have achieved ISO27001 certifications at all our Fabs.